Deep Drawing

Introduction:

A process in which a punch forces a

flat sheet metal blank into a die cavity is called a deep drawing. Through this

process we can also produce shallow or moderate depth components parts. It is

important metal working process because it is widely used in manufacturing. Normally, this process is useful in producing

deep parts with relatively simple shapes, with high production rate. There are

many parts made by this technique like pots, pans, all the types of containers

for food and beverages. The tooling and equipment cost is relatively high.

This sheet metal forming process

designed to produce hollow shells, was developed in the mid-19th century. The

company started producing porcelain-enamel-covered iron cookware between 1863

and 1870, one of the first U.S. companies to do so.

Operations:

Drawing of a cup-shaped part is the

basic drawing operation, with dimensions and parameters as pictured in Figure 1.

A blank of diameter Db is drawn into a die cavity by means of a

punch with diameter Dp. The punch and die must have corner radii,

given by Rp and Rd. If the punch and die were to have

sharp corners (Rp and Rd = 0), a hole-punching operation

(and not a very good one) would be accomplished rather than a drawing

operation. The sides of the punch and die are separated by a clearance c. This

clearance in drawing is about 10% greater than the stock thickness:

C = 1.1*t

The punch applies a downward force

F to accomplish the deformation of the metal, and a downward holding force Fh

is applied by the blank holder, as shown in the sketch.

As the punch proceeds downward

toward its final bottom position, the work experiences a complex sequence of

stresses and strains as it is gradually formed into the shape defined by the

punch and die cavity. The stages in the deformation process are illustrated in

Figure 2. As the punch first begins to push into the work, the metal is

subjected to a bending operation. The sheet is simply bent over the corner of

the punch and the corner of the die, as in Figure 2[2].

FIGURE

1 (a) Drawing of a cup shaped part: (1) start of operation before punch

contacts work, and (2) near end of stroke; and (b) corresponding work part: (1)

starting blank, and (2) drawn part. Symbols: C = clearance, Db = blank

diameter, Dp = punch diameter, Rd = die corner radius, Rp

= punch corner radius, F = drawing force, Fh = holding force.

Deep Drawability:

In a deep drawing

operation, failure generally results from the thinning of the cup wall under

high longitudinal tensile stresses. If we follow the movement of the material

as it flows into the die cavity, it can be seen that the sheet metal

(a)

Must be capable of undergoing a reduction in

width due to a reduction in diameter.

(b)

Must also resist thinning under the longitudinal

tensile stresses in the cup wall.

It

has been observed that materials with outstanding deep drawability behave anisotropically.

Plastic deformation in the surface is much more pronounced than in the

thickness. The lankford coefficient (r) is a specific material property

indicating the ratio between width deformation and thickness deformation in the

uniaxial tensile test. Materials with very good deep drawability have an r

value of 2 or below.

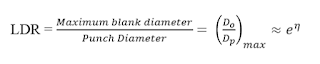

Limiting Drawing Ratio (LDR):

Deep drawability generally is

expressed by the limiting drawing ratio (LDR) and the drawability of a metal is

measured by the ratio of the initial blank diameter to the diameter of the cup

drawn from the blank (usually approximated by the punch diameter).

The theoretical upper limit on LDR is

Where ![]() is an efficiency term

to account for frictional losses. If

is an efficiency term

to account for frictional losses. If ![]() = 1, then LDR = 2.7,

while if

= 1, then LDR = 2.7,

while if ![]() = 0.7, LDR = 2. This

agrees with experience that even with ductile metals it is difficult to draw a

cup with a height much greater than its diameter [1].

= 0.7, LDR = 2. This

agrees with experience that even with ductile metals it is difficult to draw a

cup with a height much greater than its diameter [1].

So for a given material the

limiting draw ratio (LDR), represents the largest blank that can be drawn

through a die Dp without tearing.

Some of the practical

considerations which affect drawability are[1]:

·

Die

radius - should be about 10 times sheet thickness.

·

Punch

radius - sharp radius leads to local thinning and tearing.

·

Clearance

between punch and die ~20 to 40 percent greater than the sheet thickness.

·

Hold-down

pressures about 2 per cent of average of So and Su.

·

Lubricate

die side to reduce friction in drawing.

In order to have successful

drawing of cup shaped part has been found to be a function of the normal

anisotropy, R (also called plastic anisotropy), of the sheet metal.

The effect of planar anisotropy on LDR:

Due to rolling of sheet, grains elongate

into specific directions as shown in Fig. 3, so show different mechanical

properties in different directions, which is called anisotropy.

Figure 3. Rolling produce smaller and elongated grains.

The planar anisotropy of the

sheet is indicated by ![]() R. It is defined in terms of directional

R. It is defined in terms of directional ![]() R,

R,

The planar anisotropy decrease

the LDR value, which in result cause earing defect. In deep drawing, earing

defect is the formation of wavy cup of edges as shown in Fig. 4. They are objectionable

on deep drawn cups because they have to be trimmed off, as they serve no useful

purpose and interfere with further processing of cup, resulting in scrap.

Figure 3. Earing produced due to planar anisotropy.

The value of the strain hardening exponent (n) lies between 0 and 1. Most

metals have an n value between 0.10 and 0.50. What is this value representing?

The response of a metal to cold working can be quantified

by the strain-hardening exponent n. The relationship between true stress 𝞂,

true strain ε, and the strain-hardening exponent n

is governed by so-called power law behavior according to

𝞂 = K*εn

The constant K

(known as the strength coefficient) is equal to the stress when ε = 1. The

value of the strain hardening exponent (n) lies between 0 and 1. Most metals

have an n value between 0.10 and 0.50 [3].

It is actually a measure of the

ability of a metal to strain harden; the larger its magnitude, the greater is

the strain hardening for a given amount of plastic strain [4]. The value of 0 means there is no strain

hardening which indicates that it is perfectly plastic solid, greater than 0

means a little strain hardening which most of the metals shows, while value of

1 indicates that true stress and true strain are linearly dependent which

indicates that it is 100% elastic solid.

The effect of grain-size of sheet metal on the surface finish of the cup:

Grain size of sheet depend on

many factors, rolling temperature, composition and processing rote. In general,

large grain size of sheet in deep drawing operation cause orange peel effect. Orange

peel is a cosmetic defect associated with a rough surface appearance after

forming a component from sheet metal. It is called orange peel because the

surface has the appearance of the surface of an orange. But smaller grain size

results in smoother surface finish.

The effect of “too high” & “too low” blank holder force on deep

drawing:

The drawing force required to perform a given operation can be estimated roughly by the formula [1]:

Where P = total

punch load, 𝞂o=

average flow stress, Dp = punch diameter, Do = blank

diameter, H = hold-down force, B = force required to bend and restraighten

blank, h = wall-thickness, µ = coefficient of friction

If it is too

small, wrinkling occurs. If it is too large, it prevents the metal from flowing

properly toward the die cavity, resulting in stretching and possible tearing of

the sheet metal. Determining the proper holding force involves a delicate

balance between these opposing factors [2].

The purpose of the punch and die radius (𝑅𝑝, 𝑅𝐷)

and the clearance between them:

One of the measures of the

severity of a deep drawing operation is the drawing ratio DR. This is most

easily defined for a cylindrical shape as the ratio of blank diameter Db

to punch diameter Dp. In equation form,

DR = Db/

The drawing ratio provides an

indication, albeit a crude one, of the severity of a given drawing operation.

The greater the ratio, the more severe the operation. An approximate upper

limit on the drawing ratio is a value of 2.0. The actual limiting value for a

given operation depends on punch and die corner radii (Rp and Rd),

friction conditions, depth of draw, and characteristics of the sheet metal

(e.g., ductility, degree of directionality of strength properties in the

metal)[2].

As discussed earlier the clearance

between punch and die ~20 to 40 percent greater than the sheet thickness [1].

Role of Lubrication

Correct lubrication of the sheet

metal is essential if friction, wear, and galling are to be held to the lowest

possible levels during deep drawing. In fact, deep drawing is impossible if the

sheet metal is not lubricated. In actual practice, die materials are selected

after trials using one or more candidate production lubricants. If excessive

wear or galling occurs, a better lubricant is usually applied. For extremely

difficult draws, the best lubricants are usually applied at the outset [5].

References

[1] Dieter, George Ellwood, and D. J.

Bacon. 1988. Mechanical

metallurgy. London: McGraw-Hill.

[2] Groover, Mikell

P., 1939-. Fundamentals of Modern Manufacturing: Materials, Processes, and

Systems. Hoboken, NJ:J. Wiley & Sons, 2007.

[3] Askeland,

Donald R. 1984. The science and

engineering of materials. Monterey, CA: Brooks/Cole Engineering

Division.

[4] Callister, William D., and David G.

Rethwisch. 2008. Fundamentals of

materials science and engineering: an integrated approach. Hoboken, NJ:

John Wiley & Sons.

[5] ASM International. 2006. ASM Handbook. Volume 14B, Volume 14B.

https://doi.org/10.31399/asm.hb.v14b.9781627081863.