Argon Oxygen Decarburization (AOD)

Argon oxygen decarburization offers

improved metal cleanliness, which is measured by low unwanted residual element

contents and gas contents; this ensures superior mechanical properties. The AOD

process is duplexed, with molten metal supplied from a separate melting source

to the AOD refining unit (vessel). The source of the molten metal is usually an

electric arc furnace or a coreless induction furnace. Foundries and integrated

steel mills utilize vessels ranging in nominal capacity from 1 to 160 Mg (1 to

175 tons).

Although the process was initially

targeted for stainless steel production, argon oxygen decarburization is used

in refining a wide range of alloys, including:

v

Stainless steels

v

Tool steels

v

Silicon (electrical) steels

v

Carbon steels, low-alloy steels, and

high-strength low-alloy steels

v

High-temperature alloys and superalloys

Fundamentals

In the AOD process, oxygen, argon,

and nitrogen are injected into a molten metal bath through submerged,

side-mounted tuyeres. The primary aspect of the AOD process is the shift in the

decarburization thermodynamics that is afforded by blowing with mixtures of

oxygen and inert gas as opposed to pure oxygen.

To understand the AOD process, it

is necessary to examine the thermodynamics governing the reactions that occur

in the refining of stainless steel, that is, the relationship among carbon,

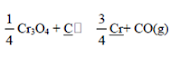

chromium, chromium oxide (Cr3O4), and carbon monoxide (CO). The overall

reaction in the decarburization of chromium-containing steel can be written as:

The equilibrium constant, K, is given by:

At a given temperature, there is a

fixed, limited amount of chromium that can exist in the molten bath that is in equilibrium

with carbon. By examining Eq 2, one can see that by reducing the partial

pressure of CO, the quantity of chromium that can exist in the molten bath in

equilibrium with carbon increases. The partial pressure of CO can be reduced by

injecting mixtures of oxygen and inert gas during the decarburization of

stainless steel. Figure 1 illustrates the relationship among carbon, chromium,

and temperature for a partial pressure of CO equal to 1 and 0.10 atm (1000 and 100

mbar, or 760 and 76 torr). The data shows that diluting the partial pressure of

CO allows lower carbon levels to be obtained at higher chromium contents with

lower temperatures.

Fig. 1 Carbon-chromium equilibrium curves.

In refining stainless steel, it is

generally necessary to decarburize the molten bath to less than 0.05% C.

Chromium is quite susceptible to oxidation; therefore, prior to the

introduction of the AOD process, decarburization was accomplished by

withholding most of the chromium until the bath had been decarburized by oxygen

lancing. After the bath was fully decarburized, low-carbon ferrochromium and

other low-carbon ferroalloys were added to the melt to meet chemical

specifications.

Dilution of the partial pressure of

CO allows the removal of carbon to low levels without excessive chromium

oxidation. This practice enables the use of high-carbon ferroalloys in the

charge mix, avoiding the substantially more expensive low carbon ferroalloys.

Fig.

2 Composition changes in refining type 304-L stainless steel using electric

arc furnace practice and argon oxygen decarburization

Equipment

The processing vessel consists of a

refractory-lined steel shell mounted on a tiltable trunnion ring (Fig. 2). With

a removable, conical cover in place, the vessel outline is sometimes described

as pear shaped. Several basic refractory types and various quality levels of

the refractories have gained widespread acceptance (Ref 4, 5). Dolomite

refractories are used in most AOD installations; magnesite chromium

refractories are predominant in small (<9 Mg, or 10 ton) installations.

Fig.

2 Schematic of argon oxygen decarburization vessel.

Processing

1.

Stainless Steels

Charge materials (scrap and

ferroalloys) are melted in the melting furnace. The charge is usually melted

with the chromium, nickel, and manganese concentrations at midrange

specifications. The carbon content at meltdown can vary from 0.50 to 3.0%,

depending on the scrap content of the charge. Once the charge is melted down,

the heat is tapped, and the slag is removed and weighed prior to charging the

AOD vessel.

In the refining of stainless steel

grades, oxygen and inert gas are injected into the bath in a stepwise manner.

The ratio of oxygen to inert gas injected decreases (3:1, 1:1, 1:3) as the

carbon level decreases. Once the aim carbon level is obtained, a reduction mix

(silicon, aluminum, and lime) is added. If extra-low sulfur levels are desired,

a second desulfurization can be added. Both of these steps are followed by an

argon stir. After reduction, a complete chemistry sample is usually taken and

trim additions made following analysis.

Carbon and Low-Alloy Steels

The refining of carbon and

low-alloy steels involves a two-step practice: a carbon removal step, followed

by a reduction/heating step. The lower alloy content of these steels eliminates

the need for injecting less than a 3:1 ratio of oxygen to inert gas. Once the

aim carbon level is obtained, carbon steels are processed similarly to

stainless steels. Figure 5 illustrates carbon content and temperature relationship

for the AOD refining of carbon and low-alloy steels. Because the alloy content

of these grades of steel is substantially lower than that of stainless steel

and because the final carbon levels are generally higher, there is no

thermodynamic or practical reason for using an oxygen, inert-gas ratio of less

than 3:1.

Oxidation measurements indicate

that all of the oxygen reacts with the bath and that none leaves the vessel

unreacted. By monitoring and recording the oxygen consumption during refining,

very close control of end point carbon is achieved. Because the oxygen and

inert gases are introduced below the bath and at sonic velocities, there is

excellent bath mixing and intimate slag/metal contact. As a result, the

reaction kinetics of all chemical processes that take place within the vessel

are greatly improved.

Decarburization

In both stainless and low-alloy

steels, the dilution of oxygen with inert gas results in increased carbon

removal efficiencies without excessive metallic oxidation. In stainless grades,

carbon levels of 0.01% are readily obtained.

Chemistry Control

The excellent compositional control of AOD-refined steel is indicated in Table 2 for a ten-heat series of high-strength low-alloy steel. The injection of a known quantity of oxygen with a predetermined bath weight enables the steelmaker to obtain very tight chemical specifications.

No comments:

Post a Comment